Stainless Steel Suppliers

Ungakwazi ukufaka insimbi engagqwali?

Ukufaka insimbi engagqwali kungase kubonakale kuwumsebenzi onzima, kodwa akunakwenzeka. Zicabange ungumcwebi, unikezwe umsebenzi wokulungisa ifa lomndeni elithandekayo elenziwe ngensimbi engagqwali. Uyazi ukuthi ukushisela akuyona inketho, kodwa ikhasimende lifuna ucezu lubukeke luhle njengokusha. Wenzani? Uphendukela ku-soldering.

Nawe ungakwenza solder insimbi engagqwali?

Yebo, i-soldering steel stainless inzima ngoba inezinga eliphezulu lokuncibilika futhi ayikwamukeli kalula i-solder. I-welding noma i-brazing ngokuvamile isetshenziswa esikhundleni salokho.

Ngamathuluzi nezindlela ezifanele, i-Welding noma i-brazing ingaba yindlela enhle yokuhlanganisa insimbi engagqwali ngaphandle kokulimaza ucezu. Kulesi sihloko, sizohlola i-ins and outs of soldering steel stainless steel, futhi sikubonise ukuthi kungenzeka ukudala isibopho esiqinile nesinhle esizohlala iminyaka eminingi ezayo. Ngakho-ke, uma ufuna ukwazi ukuthi ungakwazi yini ukudayisa insimbi engagqwali noma cha, qhubeka ufunda.

Yiziphi izinhlobo ezahlukene zezindlela zokuhlanganisa zensimbi engagqwali?

Kunezindlela eziningana zokuhlanganisa insimbi engagqwali, ngayinye inezinzuzo zayo kanye nokubi. Izindlela ezivame kakhulu zihlanganisa:

I-Silver brazing:

Le ndlela isebenzisa ingxubevange yesiliva ukwakha isibopho esiqinile, esiqinile phakathi kwezingcezu zensimbi engagqwali.I-TIG Welding:

I-Tungsten Inert Gas (TIG) welding nayo ingasetshenziselwa ukuhlanganisa insimbi engagqwali. Le ndlela isebenzisa i-electrode ye-tungsten ukushisa insimbi kanye nenduku yokugcwalisa ukuze ihlanganise izingcezu.Ukushisela kwe-MIG:

I-Metal Inert Gas (MIG) welding nayo ingasetshenziselwa ukuhlanganisa insimbi engagqwali. Le ndlela isebenzisa okuphakelayo kocingo kanye negesi engasebenzi ukuze kwakhe isibopho esiqinile phakathi kwezingcezu.I-Resistance welding:

Le ndlela isebenzisa ukumelana nogesi ukushisa insimbi engagqwali futhi idale isibopho phakathi kwezingcezu.I-Laser Welding:

Le ndlela isebenzisa i-laser enamandla amakhulu ukushisa nokuhlanganisa izingcezu zensimbi engagqwali.

Ukukhethwa kwendlela kuzoncika ekusetshenzisweni okukhethekile kanye nezidingo zamandla, ukuqina, nokumelana nokugqwala. Kubalulekile ukukhetha indlela ezohlinzeka ngesibopho esiqinile nesithembekile sokusetshenziswa okuhlosiwe.

Hlobo luni lwe-solder okufanele lusetshenziselwe insimbi engagqwali?

Lapho uhlanganisa insimbi engagqwali, kubalulekile ukukhetha uhlobo olufanele lwe-solder. Ngokuvamile, ama-solder anokuqukethwe okuphezulu kwesiliva anconywa ngoba anikeza amandla angcono okubopha kanye nokumelana nokugqwala. Ama-alloys avamile ensimbi engagqwali ahlanganisa ama-solder asekelwe esiliva, njengalawo aqukethe isiliva, ithusi, ne-zinc.

Kubalulekile futhi ukusebenzisa i-flux eyakhelwe ngokukhethekile insimbi engagqwali. I-flux isiza ukuvimbela i-oxidation ngesikhathi senqubo ye-solder futhi ikhuthaza ukunamathela phakathi kwe-solder ne-stainless steel surface. Amanye ama-fluxes anconyiwe okufakwa kwensimbi engagqwali ahlanganisa lawo aqukethe i-boron, i-zinc chloride, noma i-ammonium chloride.

Kubalulekile ukulandela imiyalelo yomkhiqizi yakho kokubili i-solder ne-flux ukuze uqinisekise ukubopha okufanele futhi ugweme noma yiziphi izinkinga ezingase zibe nokugqwala noma amandla. Ukwengeza, kubalulekile ukuhlanza kahle futhi ulungise indawo yensimbi engagqwali ngaphambi kokusoda ukuze uqinisekise ibhondi eqinile nehlala isikhathi eside.

Ingabe kunzima ukudayisa insimbi engagqwali uma kuqhathaniswa nezinye izinto?

Yebo, ukunamathisela insimbi engagqwali kungaba inselele kakhulu kunezinye izinto ngenxa ye-thermal conductivity ephezulu kanye ne-coefficient ephansi yokwandisa okushisayo.

Kudinga izinga lokushisa eliphezulu kanye nohlobo olukhethekile lokuguquguquka ukuze kukhishwe ungqimba lwe-chromium oxide oluvikela insimbi engagqwali ekugqwaleni. Ukwengeza, insimbi engagqwali inomkhuba wokusonteka nokuhlanekezela lapho ivezwe ekushiseni, okwenza kubaluleke ukusebenzisa amasu nemishini efanele ukuze kuvinjelwe umonakalo.

Kodwa-ke, ngokulungiselela kahle, izinto ezisetshenziswayo nezinto ezisetshenziswayo ezifanele, kanye nezindlela ezinhle, ukuhlanganisa insimbi engagqwali kungafezwa ngempumelelo. Ama-welders anolwazi nabasebenzi bensimbi bavame ukuzuza imiphumela emihle kakhulu nge-stainless steel soldering.

Ingabe insimbi engagqwali ingathengiswa ngaphandle kokusebenzisa i-flux?

Yes, ukuguga kwensimbi engagqwali ngaphandle kokuguquguquka kungenzeka, kodwa akunconywa.

I-Flux isiza ukususa noma yimaphi ama-oxide noma ukungcola ebusweni bensimbi engagqwali, okuvumela i-solder ukuthi ihlangane kahle. Ngaphandle kwe-flux, i-solder ingase inganamatheli kahle, okuholela ekuhlanganiseni okubuthakathaka noma okungaphelele. Ukwengeza, ngaphandle kwe-flux, inqubo ye-soldering ingase ithathe isikhathi eside, futhi amathuba okushisa noma ukulimaza insimbi engagqwali ayanda. Kungcono ukusebenzisa i-flux efanelekile ye-solder yensimbi engagqwali ukuze uqinisekise imiphumela engcono kakhulu. Uhlobo lwe-flux esetshenziswayo luncike endleleni ye-soldering kanye ne-alloy ethize yensimbi engagqwali ethengiswayo. Ukusebenzisa i-flux engalungile kungaholela kwikhwalithi ehlangene engalungile noma ngisho nokugqwala ngokuhamba kwesikhathi. Ngakho-ke, kubalulekile ukuthintana nochwepheshe noma ubheke imihlahlandlela yomkhiqizi ukuze uqinisekise ukuthi kusetshenziswa ukugeleza okulungile enqubweni yokuhlanganisa.

Ungakwazi yini ukudayisa amamaki ahlukene ensimbi engagqwali ndawonye?

Cha. Ukusoda amabanga ahlukene ensimbi engagqwali ndawonye kungaba inselele ngenxa yamazinga ahlukahlukene wokuqukethwe kwe-alloy nokwakheka.Kunconywa ukuba ugweme ukunamathisela amamaki ahlukene ensimbi engagqwali, njengoba kungaholela ekugqwaleni nasezintweni zemishini ezisengozini.

Kodwa-ke, uma i-soldering kudingekile, kubalulekile ukusebenzisa i-solder ehambisana nawo womabili amamaki ensimbi engagqwali futhi ucabange ngokucophelela ukuklama okuhlangene nokulungiselela ukuze kuqinisekiswe isibopho esiqinile nesiqinile. Ukushisela noma ukubhula kungaba izinketho ezingcono zokujoyina amamaki ahlukene ensimbi engagqwali. Kuhlale kunconywa ukuthi uthintane ne-metallurgist noma unjiniyela wokushisela ngaphambi kokuzama ukudayisa amamaki ahlukene ensimbi engagqwali ndawonye.

Yikuphi izinga lokushisa elidingekayo ukuze solder insimbi engagqwali?

Izinga lokushisa elidingekayo ukuze i-solder insimbi engagqwali incike ohlotsheni lwe-solder kanye ne-flux esetshenziswayo. Ngokuvamile, izinga lokushisa eliphakathi kuka-600 no-800 degrees Fahrenheit liyadingeka ukuze kuncibilike i-solder futhi kwakhiwe isibopho ngensimbi engagqwali. Kubalulekile ukuqaphela ukuthi ukushisa ngokweqile kwensimbi engagqwali kungabangela ukulimala kwezakhiwo zayo futhi kuholele ekwakhekeni kwezindawo ezithintekayo ukushisa.

Ukwengeza, kubalulekile ukusebenzisa i-soldering iron noma ithoshi elinokulawula ukushisa okuhle ukuvimbela ukushisa nokuqinisekisa ukushisa okungaguquki kokuhlangana kwe-solder. Kubuye kunconywe ukusebenzisa inkomba yokushisa efana ne-thermocouple ukuqapha izinga lokushisa elihlangene ngesikhathi senqubo yokuhlanganisa.

Sekukonke, izinga lokushisa elidingekayo ukuze i-soldering insimbi engagqwali iphakeme kunaleyo edingekayo ukuze kuhlanganiswe ezinye izinto ezifana nethusi noma ithusi, futhi kubalulekile ukulandela amasu afanele wokuhlanganisa ukuze kuzuzwe ukuhlanganiswa okuqinile nokuqinile.

Ingabe zikhona izinyathelo zokuphepha okufanele uzithathe lapho u-soldering insimbi engagqwali?

Yibe, thkukhona izinyathelo zokuphepha ezimbalwa okufanele uzithathe lapho u-soldering insimbi engagqwali. Okokuqala futhi okubaluleke kakhulu, kubalulekile ukuba sebenza endaweni enomoya omuhle ukugwema ukuhogela noma iyiphi intuthu ekhiqizwa ngesikhathi sokusoda. Kubalulekile futhi uku gqoka izinto zokuzivikela, njengamagilavu nezingilazi zokuphepha, ukuvimbela ukusha nokuchayeka ekugugeni kwe-soldering.

Ukwengeza, kubalulekile ukuba sebenzisa i-soldering iron enokulawula ukushisa ukugwema ukushisa ngokweqile insimbi engagqwali, okungabangela ukushintsha kombala futhi kwenze buthaka impahla. Kubuye Kunconywa ukuba sebenzisa i-soldering paste noma i-flux eyakhelwe ngokukhethekile insimbi engagqwali ukuqinisekisa isibopho esiqinile futhi uvimbele umonakalo impahla.

Ekugcineni, kubalulekile landela izinqubo ezifanele zokulahla noma yiziphi izinto ezilahlwayo ezikhiqizwa ngesikhathi senqubo yokuhlanganisa, njenge-soldering flux esetshenzisiwe kanye nezinsalela ze-solder. Lezi zinto zingaba yingozi emvelweni uma zingalahlwanga kahle.

Ukushuba kwensimbi engagqwali kuyithinta kanjani inqubo yokuhlanganisa?

Ubukhulu bensimbi engagqwali bungathinta inqubo ye-soldering ngezindlela ezimbalwa. Insimbi ewugqinsi idinga ukushisa okwengeziwe ukuze kusetshenziswe ukuze i-solder igeleze kahle futhi ihlangane nensimbi. Lokhu kungenza inqubo ibe inselele kakhulu, njengoba insimbi ingasonteka noma yonakale uma kufakwa ukushisa okukhulu. Ukwengeza, insimbi ewugqinsi ingadinga isikhathi eside sokushisa, okungase kwenyuse ingozi yokushisisa kwe-solder noma ukushiswa kwe-flux ngokushesha okukhulu.

Ngakolunye uhlangothi, insimbi ezacile ingaba lula kakhulu ekujikeni noma ekuncibilikeni uma kusetshenziswa ukushisa okukhulu. Kungase futhi kube nzima nakakhulu ukwakha isibopho esiqinile phakathi kwe-solder nensimbi uma insimbi incane kakhulu.

Ngakho-ke, kubalulekile ukucabangela ukushuba insimbi engagqwali lapho uhlela inqubo soldering. Ukulawula izinga lokushisa ngendlela efanele kanye nezinqubo kubalulekile ukuze kuzuzwe isibopho esiphumelelayo nesiqinile phakathi kwe-solder nensimbi, kungakhathaliseki ukuthi ubukhulu bayo bunjani.

Yiziphi ezinye izinhlelo zokusebenza ezivamile lapho i-soldering isetshenziswa ensimbi engagqwali?

I-soldering ivame ukusetshenziswa ezinhlotsheni ezihlukahlukene lapho kuhileleke insimbi engagqwali. Ezinye izibonelo ezivamile zihlanganisa ukwenza ubucwebe, ukuhlanganiswa kwe-electronics, amapayipi, nokulungiswa kwezimoto.

Ekwenziweni kobucwebe, i-soldering isetshenziselwa ukuhlanganisa izingxenye ezihlukahlukene zesiqephu, njengama-clasps namaketanga. Emhlanganweni we-elekthronikhi, i-soldering isetshenziselwa ukunamathisela izingxenye kumabhodi wesifunda aphrintiwe. Emapayipini, i-soldering isetshenziselwa ukuhlanganisa amapayipi ethusi ekufakweni okwenziwe ngensimbi engagqwali. Ekulungiseni izimoto, i-soldering isetshenziselwa ukulungisa izinhlelo zokukhipha umoya nezinye izinto ezenziwe ngensimbi engagqwali.

I-Soldering inikeza indlela engabizi futhi ephumelelayo yokujoyina izingxenye zensimbi engagqwali, ikakhulukazi ezimeni lapho ukushisela kungase kungabi usizo noma kudingeke. Kodwa-ke, kubalulekile ukukhetha indlela efanelekile ye-soldering kanye nezinto zokwakha zohlelo oluthile ukuze kuqinisekiswe ukuhlangana okuqinile nokuqinile. Ukwengeza, kufanele kuthathwe izinyathelo zokuphepha ukuze kuvikelwe ukushisa nentuthu ekhiqizwa ngesikhathi sokusoda.

Isiphetho

Ekuphetheni, i-soldering ingaba yisisombululo esisebenzayo sokujoyina noma ukulungisa insimbi engagqwali, kodwa kudinga amasu athile nezinto zokwakha. Kunezinhlobo ezahlukene zezindlela zokuhlanganisa insimbi engagqwali, futhi indlela efanele incike ekusetshenzisweni okuqondile kanye nohlobo lwensimbi engagqwali esetshenziswayo. Lapho u-soldering insimbi engagqwali, kubalulekile ukusebenzisa i-solder efanele kanye ne-flux ukuqinisekisa isibopho esiqinile nesiqinile. Ukwengeza, kufanele kuthathwe izinyathelo zokuphepha ezifanele, futhi ukushuba kwensimbi engagqwali kungathinta inqubo ye-solder. Nakuba i-soldering ingaba yisixazululo esiwusizo, kungase kungabi njalo indlela engcono kakhulu noma ehlala njalo yokulungiswa kwensimbi engagqwali. Ezinye izinhlelo zokusebenza ezijwayelekile zokusoda kunsimbi engagqwali zifaka amasistimu e-HVAC, okokusebenza kwezokwelapha, nezingxenye ze-aerospace. Sekukonke, i-soldering ephumelelayo yensimbi engagqwali idinga ukunakwa ngokucophelela kwemininingwane kanye nezindlela ezifanele zokuqinisekisa isibopho esiqinile nesithembekile.

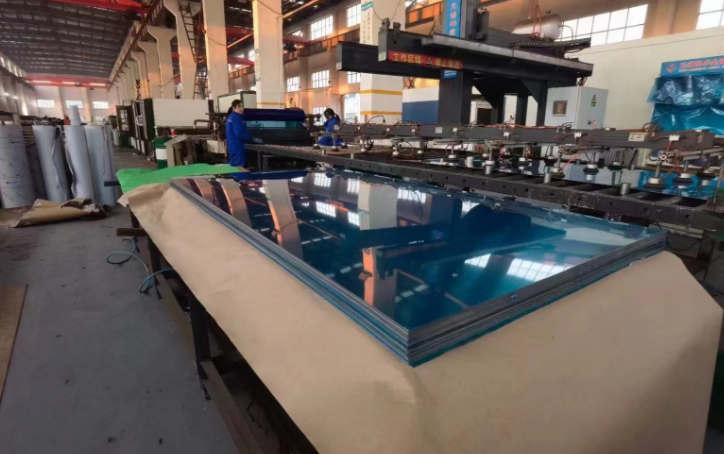

Uma ufuna ukuthola umphakeli othembekile wensimbi engagqwali, singakucebisa ukuthi ucabangele I-Sino Stainless Steel. Njengomphakeli ohamba phambili wemikhiqizo yensimbi engagqwali, iSino Stainless Steel inikeza amakhasimende insimbi engagqwali emapheshana, amakhoyili ensimbi engagqwali, amapuleti ensimbi engagqwali, amashidi ensimbi engagqwali, imigoqo yensimbi engagqwali, Futhi izintambo zensimbi engagqwali ngentengo yokuncintisana kakhulu.

Thola i-Quote Free

Uhlu Okuqukethwe

Posts Related

What is ASTM standard for SS round bar?

Stainless steel (SS) round bars occupy a pivotal position due to their widespread applications in various industries. The ASTM standard for SS round bar is

Iyini intengo yebha eyindilinga ye-SS?

Intengo ye-SS round bar iyisihloko esiyinkimbinkimbi, esithonywa yizici ezahlukahlukene kusukela ezindlekweni zezinto ezingavuthiwe, izinqubo zokukhiqiza, isidingo semakethe, kanye nokunikezwayo.

Uyini umehluko phakathi kwe-strip neshidi lensimbi?

Emkhakheni we-metallurgy nobunjiniyela bezinto zokwakha, i-strip neshidi lensimbi amagama amabili avame ukusetshenziswa ngokushintshana, kodwa empeleni, anawo.

Iyini intengo yeshidi lensimbi engagqwali engu-410?

Emkhakheni we-metallurgy nesayensi yezinto zokwakha, amashidi ensimbi engagqwali athatha isikhundla esibalulekile ngenxa yokumelana nokugqwala kwawo okukhethekile nokuqina. Phakathi kwe

Uyini umehluko phakathi kwekhoyili yeshidi nepuleti?

Njengochwepheshe osemnkantshubomvu emkhakheni wezinto zensimbi ezivela ku-Sino Stainless Steel, ngihlangabezane nezinhlobo eziningi zamafomu ensimbi, ngalinye lisebenza ngendlela yalo.

: + 86-18621535697

: + 86-18621535697  :export81@huaxia-intl.com

:export81@huaxia-intl.com